In the world of automation and control systems, understanding velocity ramps is crucial for optimizing performance and enhancing efficiency. This post will delve into what velocity ramps are, the differences between various types, and their applications in different industries.

What is a Velocity Ramp?

A velocity ramp is a controlled change in speed over a specific period. It allows systems, such as motors or robots, to accelerate or decelerate smoothly rather than abruptly starting or stopping. This gradual transition helps prevent mechanical stress and enhances the lifespan of machinery while improving overall process efficiency.

Key Components of a Velocity Ramp:

- Acceleration Phase: The time during which the speed increases from a standstill to a predetermined maximum speed.

- Constant Velocity Phase: The period during which the system maintains a steady speed for a designated time.

- Deceleration Phase: The time taken to reduce the speed back to a stop or a lower speed.

Types of Velocity Ramps

Velocity ramps can vary based on the specific requirements of the application. Below are the primary types along with their key parameters:

- Linear/Trapezoidal Ramp:

- Definition: A linear ramp increases or decreases speed at a constant rate. The trapezoidal shape includes a flat top where the speed is constant before deceleration.

- Parameters:

- Acceleration Time (t_acc): Time taken to reach maximum speed.

- Deceleration Time (t_dec): Time taken to reduce speed back to zero.

- Maximum Velocity (v_max): The peak speed achieved during the constant velocity phase.

- Applications: Commonly used in systems where consistent control is necessary, such as conveyor belts and basic robotics.

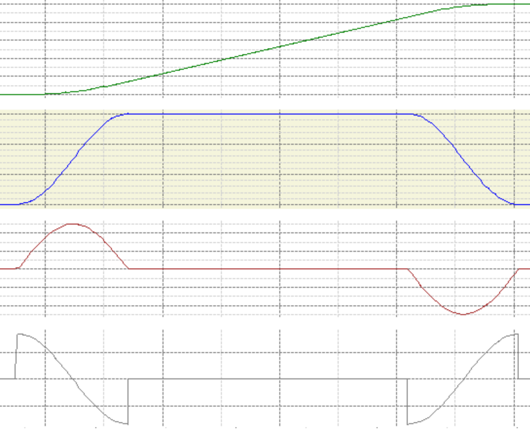

- Sine² Ramp:

- Definition: This ramp utilizes a sine squared function to create a smooth acceleration and deceleration profile, allowing for gradual transitions.

- Parameters:

- Total Time (t_total): The total duration of the ramp, including acceleration and deceleration phases.

- Maximum Velocity (v_max): The peak speed achieved.

- Applications: Ideal for applications requiring smooth transitions, such as robotic arms or conveyor systems that handle delicate materials.

- Quadratic Ramp:

- Definition: This ramp uses a quadratic function to create a smooth acceleration profile, typically resulting in a curve that accelerates slowly at first and then speeds up more rapidly.

- Parameters:

- Total Time (t_total): The total duration of the ramp.

- Acceleration Factor (k): A constant that determines the rate of acceleration.

- Maximum Velocity (v_max): The peak speed achieved during the ramp.

- Jerk: Jerk is a critical consideration here, as quadratic ramps are designed to minimize jerk by providing a smooth transition in acceleration.

- Applications: Suitable for applications needing gradual acceleration, such as precision CNC machining.

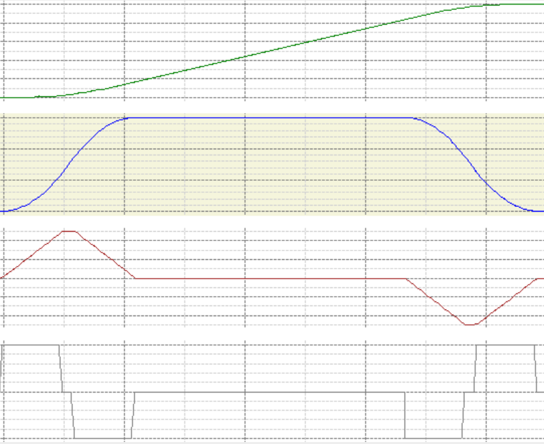

- Quadratic Smooth Ramp:

- Definition: This ramp combines the principles of a quadratic ramp with a smoothing factor, providing a very gradual start and end to the acceleration and deceleration phases.

- Parameters:

- Total Time (t_total): The overall duration for the entire ramping process.

- Smoothing Factor (s): A parameter that controls the degree of smoothness in the acceleration and deceleration phases.

- Maximum Velocity (v_max): The peak speed reached.

- Jerk: The design of this ramp ensures that jerk remains minimal, leading to smooth operation

- Applications: Often found in robotics and automated systems where maintaining smooth motion is critical to avoid mechanical stress.

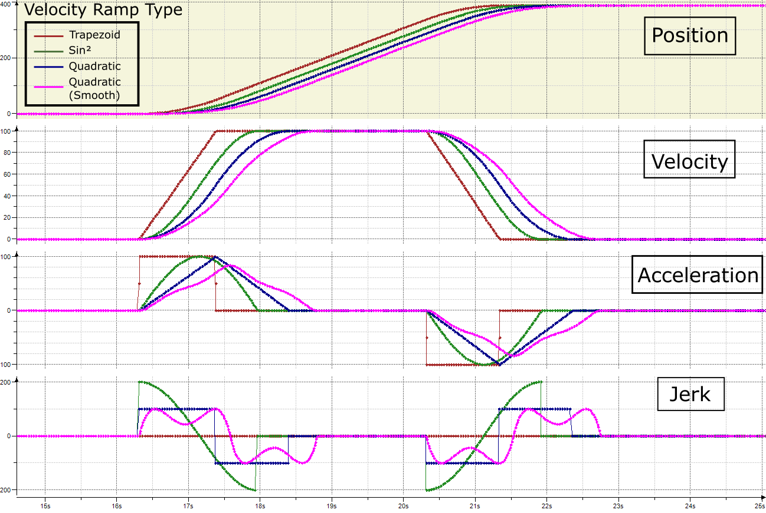

Comparison of Velocity Ramps

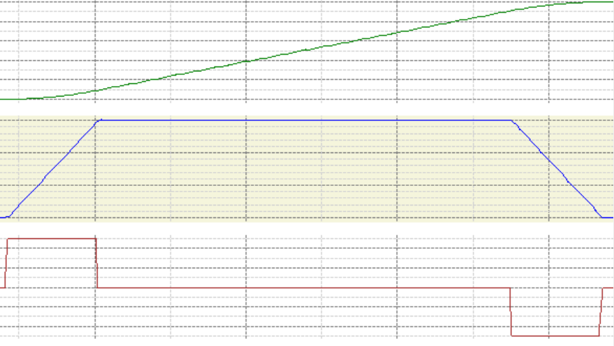

To better understand the differences between these types of velocity ramps, the following figure visually compares their profiles, illustrating how each ramp behaves in terms of position, velocity, acceleration, and jerk. The diagram below highlights the distinctions between the four types of ramps, showcasing their unique characteristics in a clear and informative manner.

- Position: The total distance covered during the acceleration and deceleration phases.

- Velocity: The speed at which the system operates at different points in time.

- Acceleration: The rate of change of velocity, showcasing how quickly the ramp reaches its maximum speed.

- Jerk: The rate of change of acceleration, indicating how smoothly the system transitions between changes in speed.

This visual comparison aids in comprehending how each ramp type can be utilized effectively based on the specific requirements of an application.

Understanding Jerk in Velocity Ramps

In addition to position, velocity, and acceleration, another critical factor to consider in velocity ramps is jerk—the rate of change of acceleration. Jerk plays a significant role in the overall performance and comfort of motion control systems.

- Definition: Jerk quantifies how quickly the acceleration of an object changes over time. It is the derivative of acceleration and is often expressed in units of distance per cubic time (e.g., m/s³).

- Importance: High jerk can lead to mechanical stress on components and discomfort in systems involving human interaction. Therefore, managing jerk is essential for optimizing performance and enhancing user experience.

- Application in Quadratic Smooth Ramps: The quadratic smooth ramp is designed to minimize jerk, providing a gradual transition in acceleration. This characteristic is particularly valuable in applications like robotics and transportation, where maintaining smooth motion is critical.

Applications of Velocity Ramps

Velocity ramps are integral to various industries and applications. Here are a few notable examples:

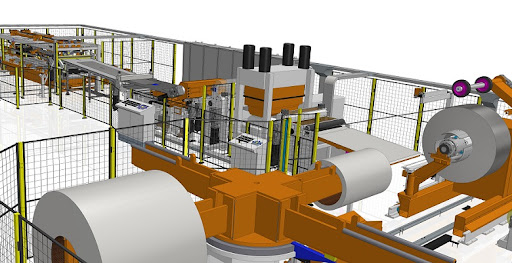

- Manufacturing: In automated assembly lines, velocity ramps ensure that machines operate smoothly, preventing parts from jostling during high-speed transitions.

- Robotics: Robots use velocity ramps to execute precise movements, improving both speed and accuracy while reducing wear on mechanical components.

- Transportation: In systems like elevators, velocity ramps enhance passenger comfort by providing a smooth transition between stops.

- CNC Machining: Velocity ramps help in maintaining precision by allowing tools to enter and exit materials smoothly, reducing the risk of damage.

Conclusion

Understanding velocity ramps is essential for optimizing system performance across various industries. By selecting the appropriate type of ramp for a specific application, manufacturers and engineers can enhance efficiency, reduce mechanical wear, and improve overall system reliability.

If you have questions or want to learn more about implementing velocity ramps in your projects, feel free to reach out!

Share Your Thoughts!

If you found this article helpful, please consider sharing it with your network. Your support helps us grow our community and spread valuable insights. Leave a comment below with your thoughts or experiences regarding velocity ramps! please consider sharing it with your network. Your support helps us grow our community and spread valuable insights. Leave a comment below with your thoughts or experiences regarding velocity ramps!